As a globally active company, we procure electronic components and system components around the globe.

This means that we are also confronted with manipulated and counterfeit components.

This risk is reduced by an extensive supplier evaluation system and further measures in advance.

In addition, our incoming goods are subjected to a series of inspections.

The extent of the inspections varies from case to case.

We attach great importance to the reliability of these processes, which is why they are an integral part of our work processes in accordance with ISO 9001.

The aim of each inspection is to identify and remove manipulated goods from circulation.

Following our motto when it comes to the testing of components:

"As little as necessary and as much is required to reach a conclusion",

we use the necessary levels of inspection on the component in agreement with our customers.

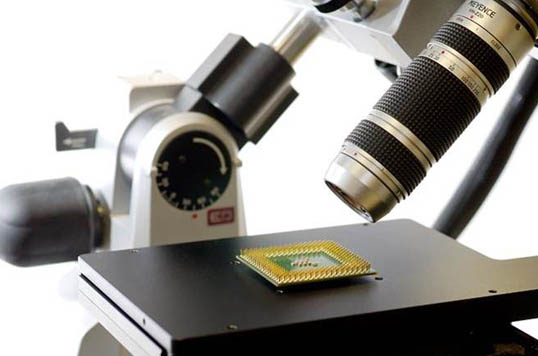

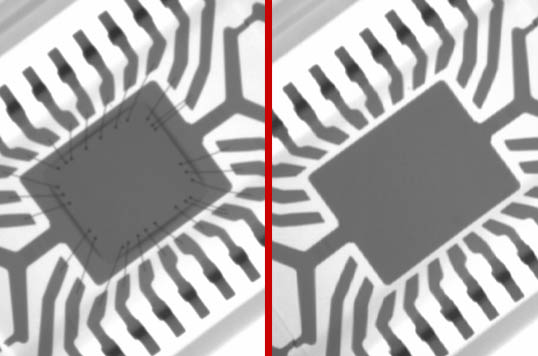

Digital microscopy

Study the surface for signs of manipulation such as; grinding marks, remarking, traces of use, scratches, blacktopping etc.

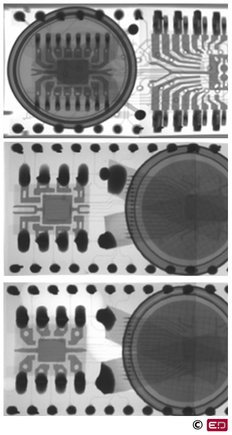

X-ray

Review of dies, lead-frames, bondings etc.

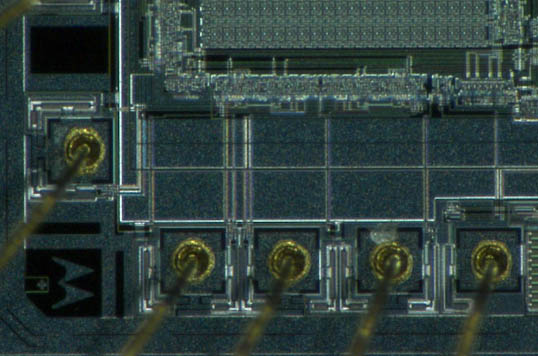

Decapsulation

Using electronic microscopy, we are able to take photographs of the manufacturer´s markings directly from the die.